Manufacturing

Manufacturing

From a spare room in an apartment to a 2000 sq.ft. facility in Chicago's West Loop. The evolution of the business and brand were closely tied. In-house manufacturing allowed speed of development in new designs, superior control of quality, and eliminated the financial burden of stocked inventory.

The Workshop

A team of six worked daily at our facility in the West Loop. We milled sheets of plastic, laminated and sanded wood, cut lenses, and laser cut leather for packaging. There is a romance to an operation buzzing with life.

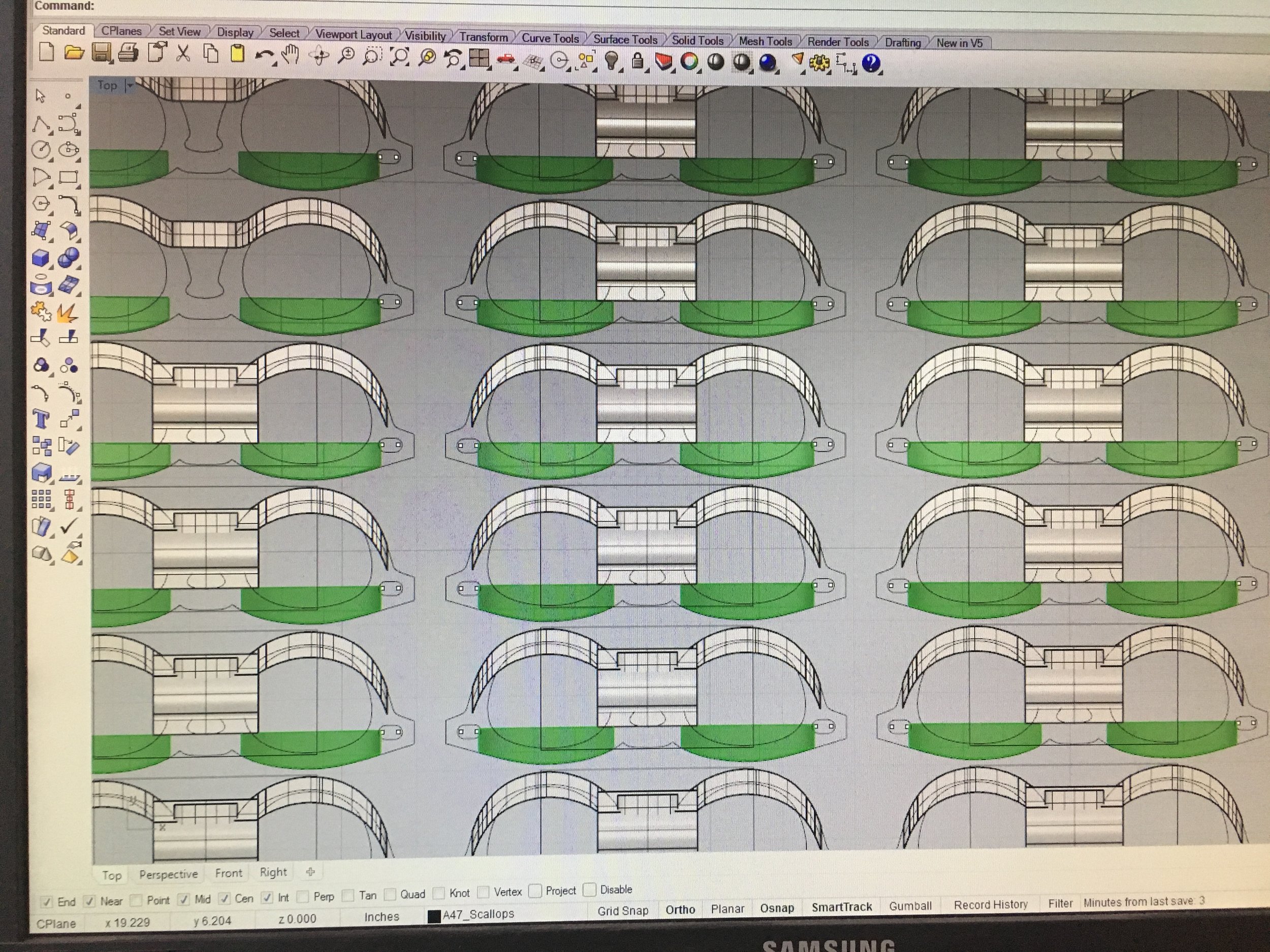

Technical development

From the start, every DRIFT design was developed in CAD. We created a custom parametric system based on human facial features. Designs were then translated to a one-off CNC process which greatly reduced tool changes.

Custom machinery & Components

With no optical frame manufacturing base in the US, we were challenged to create much of our own machinery. The large diameter polishing wheels keep a cooler surface for the fickle plastic. We came to learn that some of our DIY Hacks outperformed the industry standard.